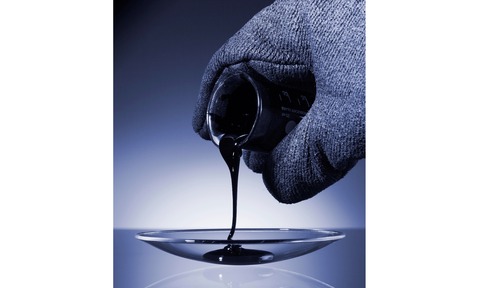

Anton Paar has published an Application Note on the use of its modular compact rheometer MCR with a plate/plate measuring system in monitoring the behaviour of bitumen at different tempuratures.

Bitumen is obtained from high temperature distillation. It is a mixture of various different petrochemical molecules connected in a physico-chemical network of forces. At low temperatures beneath the melting temperature these complex super-structures are rigid like a solid. Due to the so-called steric hardening, bitumen becomes inflexible and brittle.

When bitumen is rheologically characterised in the temperature range of T = 0 °C up to +70 °C, the sample’s state changes. With increasing temperature the mixture becomes softer and, when continuing the supply of thermal energy, the super-structures are increasingly decomposed. Thus the bitumen mass becomes more and more flexible. Under the given shear stress it is easier than for the various small

oil- and wax-like molecules and the resinous long-chained coils of macromolecules to slide off one another. However, the polymer chains usually are enclosed by interactions into the discrete, insoluble micelles or microparticles of the asphaltenes. Eventually a solid-like, rigid body becomes a free-flowing melt.

The rheological behaviour of the natural product bitumen can specifically be influenced by adding synthetic polymers. Brittle natural bitumen can be made more impact resistant by adding polymers.