Boron nanotubes test carbon strength

22 Dec 2015

Polymers that form bonds with boron nitride nanotubes are stronger that carbon nanotubes, a team of researchers has discovered.

Similar to carbon, boron nitride has the ability to form single-atom-thick sheets that can be rolled into cylinders to create nanotubes.

Alone, boron nitride nanotubes are almost as strong as their carbon counterparts, the researchers said.

However, their true advantage in a composite material comes from the way they stick strongly to the polymer, the researchers added.

Changhong Ke, an associate professor in the mechanical engineering department at the State University of New York at Binghamton, said: “The weakest link in these nanocomposites is the interface between the polymer and the nanotubes.

“If you break a composite, the nanotubes left sticking out have clean surfaces, as opposed to having chunks of polymer still stuck to them. The clean break indicates that the connection between the tubes and the polymer fails.”

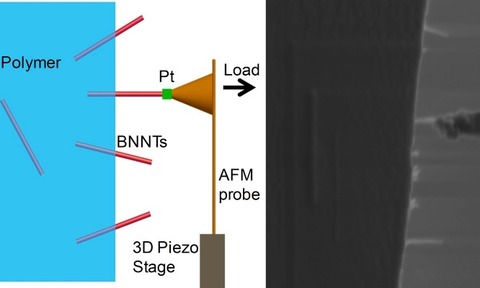

As part of the research, Ke’s team was able to test the strength of the nanotube-polymer link. It tested two forms of polymer: epoxy and PMMA, which is the same material used for Plexiglas.

The team found that the epoxy-boron nitride nanotube interface was stronger than the PMMA-nanotube interface. They also found that both polymer-boron nitride nanotube binding strengths were higher than those reported for carbon nanotubes – 35% higher for the PMMA interface and approximately 20% higher for the epoxy interface.

Boron nitride nanotubes are also more stable at high temperatures, Ke said.

However, boron nitride nanotubes are around 100 times more expensive that carbon nanotubes, the team said.

“Currently, they sell for about $1,000 per gram, compared to the $10-20 per gram for carbon nanotubes,” Ke said.

However, he said the price will likely fall, as it has with carbon nanotubes.

“I think boron nitride nanotubes are the future for making polymer composites for the aerospace industry.”