Anton Paar's SVM 3001 Stabinger Viscometer is a precise kinematic viscometer with an integrated density measuring cell.

SVM 3001 is claimed to give more parameters than any other kinematic viscometer on the market.

A single measuring cycle on a small sample volume yields kinematic viscosity, density, dynamic viscosity, viscosity index and more.

As the density cell of SVM 3001 is integrated, the density measurement does not need to be carried out separately.

One combined measuring cell covers the entire measuring range for viscosity, density and temperature and is filled in one go.

Due to its measuring principle, the measurement duration is independent of the sample’s viscosity.

A minimum sample amount of only 1.5 ml is sufficient for the multi-parameter results including calculation of API degrees.

Peltier elements allow for heating rates of up to 20°C per minute.

As the heating is electrical, no thermal transfer liquids are needed. By using the special VI method, temperature changes are performed automatically and the viscosity index is calculated in compliance with ASTM D2270.

The viscometer is designed to be easy to operate.

Injecting the sample by syringe is designed to ensure easy, safe and fast handling as well as simple cleaning with minimal risk of leakage or breakage, as well as low solvent and sample consumption.

Multiple parameters are shown on the 10x4” touch screen. Intuitive display widget shows measurement precision and repeat deviation for viscosity and density.

FillingCheck allows for monitoring of the filling quality in real time.

Accounts for all users can be created, including an audit trail option.

Storage capacity amounts to one thousand data points. Data export can be conveniently performed via USB storage device, printer or ethernet.

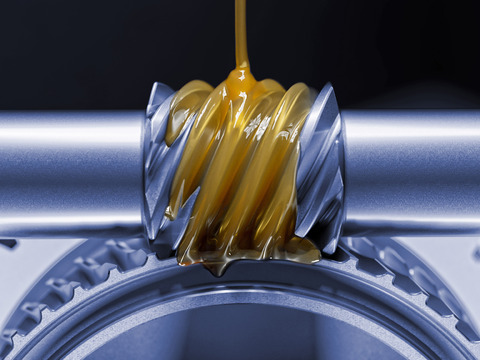

The new SVM 3001 is designed for testing of lubricating oils, base oils and additives but also grease and wax in compliance with ASTM D7042, D2270, D4052, D7152, D6074 and EN ISO 12185.