The Wellcome Trust Clinical Research Facility (CRF) in Birmingham has implemented a Brady IP Printing System, enabling it to create clear, durable labels that withstand low-temperature sample storage.

'Around 5,000 patients pass through our facility each year, generating some 2,000 blood, urine and other samples that have to be accurately labelled in accordance with MHRA regulations governing clinical trials,' said Dr Julie Williams, translational scientist and laboratory manager at the CRF.

Once these samples are divided up, as many as 160 tubes require labelling with the date, study number, patient number, sample number and other information.

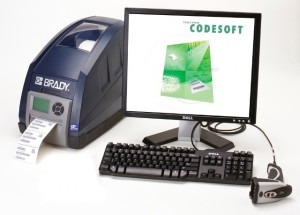

A Brady IP 300 dpi Printer, together with Brady's Codesoft label software and Freezerbondz labels, were chosen as the ideal solution to the CRF's labelling requirements.

Designed for high-performance on-demand printing, the Brady IP Printer automatically recognises the label material and ribbon loaded, checking the correct match and monitoring usage.

The latest version of Codesoft offers multiple wizards, speeding up label design and incorporation of barcodes.

'Codesoft includes a good auto date feature and makes it simple to set up a template for each study so that every label includes the correct data types in the sequence specified by the study protocol,' said Williams.

'We use Brady's Freezerbondz labels in various sizes, for 0.5 up to 20ml tubes, and the printed information remains clearly readable whether samples are placed in a 37C water bath or stored in a -80C freezer,' she added.

'The ability of the Freezerbondz material to stick to already frozen tubes is an important advantage, enabling us to replace handwritten sample information with printed labels on tubes from previous studies that are currently stored at -80C,' she said.