Anton Paar has released an application note on the high temperature tribological behaviour of advanced hard coatings for cutting tools.

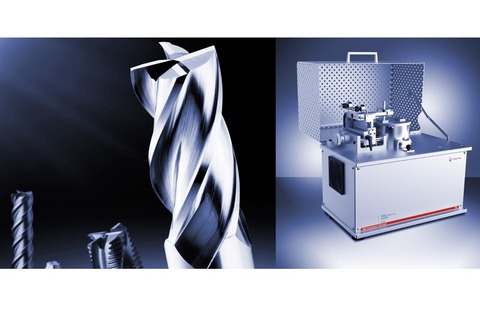

The new generation of hard coatings for cutting tools for modern machining and drilling applications shows excellent wear and abrasion resistance even at high temperatures and in harsh environment.

These coatings, based often on AlTiN, are being used in an increasing range of applications.

They have very high hardness (up to 35 GPa) and Young’s modulus (up to ~500GPa). Before putting these coatings in real life conditions, their wear and abrasion resistance as well as their hardness and adhesion must be measured.

There is a number of tests that simulate the real working conditions which are crucial for end-user.

One of the first steps in development of hard coatings is standardised pin-on-disk testing because it offers well defined environment and controlled testing conditions (applied load, rotating speed, number of laps, etc.). Such tests have proven to be an indispensable part of research and development of many hard and protective coatings in the past.

The new generation of extremely wear and abrasion resistant coatings, however, shows such high wear resistance that the common pin-on-disk tribological tests result in extremely low or almost non-measurable wear.

For efficient tribological testing and determination of wear resistance of the new hard coatings it is therefore crucial to establish a valid set of room temperature and high-temperature wear test parameters.