Prior Scientific has launched a 47 mm filter sample holder for its H101A microscope stage.

The holder is the latest addition to the company’s range of microscope sample holders - which help to increase precision, reduce operation error and enhance imaging productivity of automotive engine wear testing through automation of filtered sample inspection.

It fits on the exceptionally precise H101A microscope stage, enabling the filter paper to be analysed faster and with a repeatability of just 0.7 µm. Controlled by Prior’s powerful ProScan III control system, the stage can be easily integrated into an automated imaging system, with the potential to lead to considerable savings in both time and money.

Inspection of filters is critical in many industrial processes and to fulfil the requirements of regulations such as ISO 16232, which covers the characterisation and measurement of particulate contamination of the parts, components and assemblies which make up the fluid circuits of motor vehicle combustion engines.

It is also is important in the design and testing of engines, allowing manufacturers to identify the parts of an engine prone to wear by the metal particles caught on 47mm filters. From both a regulatory and manufacturing perspective, accurate imaging of these filter papers is essential.

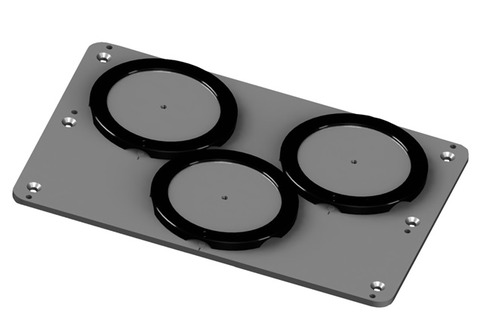

Manufactured from hard anodised aluminium, with a steel plate cover, Prior's latest sample holder is designed to hold 47mm filter papers securely, whilst delivering a viewable area of 45.5 mm in diameter - allowing almost the entire surface to be analysed. Variants which hold three and one piece of filter paper are available.