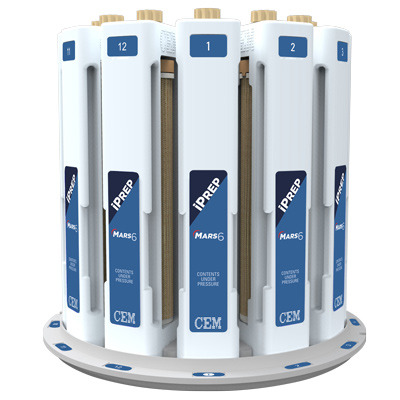

CEM, a leading exponent of microwave applications for the laboratory, have produced a new microwave digestion vessel, the iPrep, which offers significant advantages over other vessel types.

CEM produced the first microwave digestion vessel in 1986. Now, using their patented dual-seal technology, CEM have produced a new improved digestion vessel, the iPrep, which gives significant advantages over previous vessel types, particular in the digestion of difficult organic samples.

The iPrep can now digest up to twice as much sample per run, not just a saving in sampling time, but an aid to homogeneity and increased detection limits. Difficult samples like oils, boron carbide, PET and ceramics can be digested to a clear and colourless liquid, in amounts of around 0.2 - 0.5 grams using only nitric acid. An organic sample can be ramped to 250° C within 20 minutes and held there, with a temperature consistency of just a few degrees, for 40 minutes until the sample is digested. Samples contained silicates e.g. coal and toner, may require the addition of HF.

The easy-to-assemble iPrep requires only a simple hand-held tightening tool, yet the elegant dual seal pressure design retains volatile elements such as Hg, As and Se while allowing unmatched control of digestion by-products like CO2 and Nox by are venting out of a specific vent canal. Used in conjunction with the Mars 6 and their contactless iWave temperature control technology, the iPrep can reach higher temperatures, with a new degree of precision and control, to produce even higher batch consistency.

With CEM’s continued commitment to design detail and product testing, the iPrep combines the highest performance levels and the safest operating parameters to produce a degree of functionality for microwave digestion not seen prior to the advent of the iPrep.