Metrohm Inline Sample Preparation (MISP) allows for full automation, speeding up sample preparation and freeing a user to concentrate on other tasks.

Inline Ultrafiltration is recommended for use on light to moderately loaded samples (water samples, waste extracts, digestion solutions, and so on) and automates the previously manual step of sample filtration prior to IC analysis.

In IC, it is recommended to filter the sample before injection to prevent very small particles from entering the separating system that may cause problems later.

The separation column is the major consumable item with Metrohm IC and it pays to protect that investment.

Normally membrane filters with pore sizes of 0.45um or less are used for sample filtration but these are relatively expensive and physically require a person to push the sample through the syringe, which can be time-consuming.

Metrohm Inline Ultrafiltration uses standard low-cost 47mm diameter membranes (0.2um pore size) and the whole procedure is automated once the sample is introduced onto the auto sampler (sample processor) carousel.

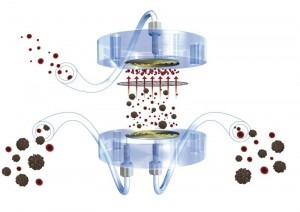

The Ultrafiltration cell is mounted directly onto the Metrohm sample processors and the bidirectional dual-channel peristaltic pump transfers the sample through the Ultrafiltration cell and to the IC system.

The sample is continuously delivered at a high flow rate that delays the formation of a filter cake and increases the working life of the membrane.

Cross-contamination is kept below 0.1 per cent.

Inline Ultrafiltration can be added to any Metrohm IC system (with the exception of the 792 Basic IC) and it is also possible to configure Ultrafiltration with third-party instruments.