A Malvern Mastersizer laser-diffraction particle-size analyser is helping to develop and evaluate mixing systems at Charles Ross and Son's Test and Development Center (Hauppauge, New York).

Ross Mixers' Premax mixer improves pigment dispersion ahead of media-milling operations in the production of inks and coatings.

Both the developers and users of the Premax employ the Mastersizer to track pigment dispersion as mixing progresses, optimising Premax operation for different applications and process conditions.

Despite huge advances in the formulation of pigment-based inks and coatings, production invariably remains a two-stage process, with the pigment being wetted out to produce the pre-mix, which is then milled to the required particle size.

Christine Banaszek, application engineer at Charles Ross and Son, said: 'Typically the focus at the pre-mixing stage is simply to achieve adequate wetting of the dry pigment.

'We wanted to develop a more efficient solution that also reduces agglomerates of particles in order to cut milling time.

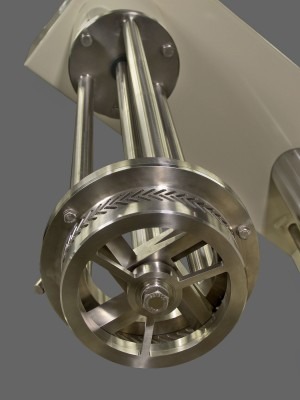

'The Delta rotor/stator of the Premax provides both high shear and vigorous flow in a batch-mixing environment.

'Clearly particle-size analysis was essential in evaluating our results, and the Mastersizer proved an excellent choice.

'Quick and easy to use, it enabled us and our customers to measure material at all stages of the process and fully test the Premax's performance,' Banaszek added.

The Mastersizer is a laser-diffraction system for the rapid measurement of dry or wet particles.

It offers versatility, a broad measurement range and reproducible sample dispersion and measurement.