Flow factor

1 May 2013

With traditional chromatography techniques reaching their limits in nanoparticle separation, Field-Flow Fractionation could become a valuable alternative.

Since its invention nearly 50 years ago, the use of Field-Flow Fractionation (FFF) has gained traction within laboratories as a valuable separations technique.

In particular, the technology has the potential to provide major benefits for scientists working on the characterisation of nanoparticles. Increasingly, labs are finding that this cannot be done using conventional chromatography.

“Scientists are conservative which is often very good,” said Rainer Jünger of FFF group, Postnova. “In this case they are reaching the limits of existing techniques like high-performance liquid chromatography (HPLC) or gel permeation chromatography (GPC). Slowly a change in thinking has begun and scientists are now looking to FFF as an intelligent solution. That’s why we say Field-Flow Fractionation is the modern alternative to chromatography.”

Slowly a change in thinking has begun and scientists are now looking to FFF as an intelligent solution

FFF is made up of a family of elution techniques which separate nanoparticles in the 1-100nm range as well as colloids up to 1 micron. Nanoparticles are difficult to separate because they are not monodispersed and can undergo changes in dynamic interactions. Challenges in the diversity of nanoparticle composition, size and shape need to be addressed. Given the limits of traditional techniques, FFF technology is now being seen as a valuable tool capable of overcoming these difficulties.

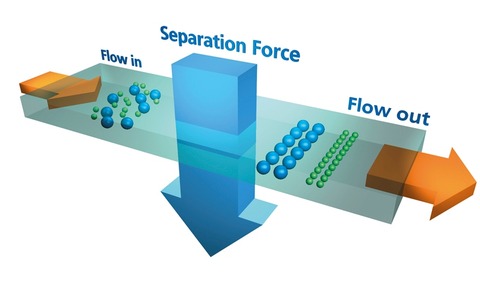

Separation during FFF occurs by differential displacement in a flowing stream of liquid that carries the separated components to a detector. The process is similar to chromatography except it uses physical forces rather than chemical reactions to separate particles. All FFF separation techniques use this same basic principle but employ different force fields. The family of techniques include Flow Field-Flow Fractionation, Sedimentation Field-Flow Fractionation, Thermal Field-Flow Fractionation or Split Flow Thin Cell Fractionation (SPLITT).

Depending on the Field-Flow Fractionation method used, different force fields are applied perpendicular to the separation channel. Under the influence of these force fields and the counteracting diffusion field, various equilibrium layers are formed by the sample analytes. For instance, with the use of centrifugal field as the controlling force for the separation, particles in the laminar flow are separated by dynamic diffusion on the basis of size and density.

Field-Flow Fractionation is the modern alternative to chromatography

This novel approach allows discrimination of materials that have the same particle size but different densities, which makes it ideal for nanoparticles and is also applicable in the microparticle size range. According to Jünger, an important benefit is that there is no static phase in FFF separation so there is no interference, allowing for far gentler separations. This is especially important for biological samples and cells, which might otherwise be damaged by being pressed through a column.

The technology has a wide range of applications in, for instance, the characterisation of challenging biopharmaceutical, food, cosmetics and nanomaterials as well as for environmental samples. Postnova, one of the leading companies developing FFF, has noted an increase in interest in the technology.

Its most popular instrument, the AF2000, is described as “the most universal FFF separator”. The AF2000 is based on the Flow FFF principle, using a crossflow field as driving force for the separation. It can be run with different eluents, at various temperature conditions and is able to employ a number of channel dimensions and principles. The same system can be used for running planar Asymmetric Flow FFF (AF4) channels or circular HollowFiber Flow FFF (HF5) channels. As a result, the AF2000 MultiFlow can be used for separation of a broad range of different samples from in biopharmaceuticals, food-agro-cosmetics, environmental, chemicals and nanotechnology.

Another player in the field, Wyatt Technology, released its Eclipse Flow-FFF separation system to market in 2001. The software controlled Eclipse system uses only one pump to generate detector flow, cross flow and injection flow. The concept to generate all three flow streams from one main flow is seen as a significant advance for the Flow-FFF method. Its fourth generation AF4 system, the Eclipse AF4, claims that it can solve the most difficult separation, fractionation and sizing tasks in the macromolecular and colloidal arenas.

With advances in the technology gaining pace, Jünger believes far more needs to be done to educate people on the benefits of FFF. Postnova’s focus in the next few years, he said, will be to help scientists understand and apply the technology in various application. “It is a matter of fact that large molecules and nanoparticles will gain more and more interest within the scientific community,” said Jünger. “It is a slow but growing market.”

A history of FFF

1966

Field-Flow Fractionation was invented by Professor Calvin Giddings at University of Utah who was twice nominated for the Nobel Prize in 1984 and in 1994.

Giddings founded the FFFresearch Center at the University of Utah in 1972. Here, Giddings and Dr Marcus Myers designed and engineered the first real FFF prototypes which later have been used as templates for the commercial product development.

1986

Giddings not only invented FFF, but also founded the world’s first FFF company, FFFractionation. The company introduced the first commercial Field-Flow Fractionation instruments globally.

It also became the first company to couple FFF with Multi-Angle Light Scattering (MALS) providing a unique set of high-resolution characterisation systems for determination of absolute molar mass and particle size of proteins, bio/polymers and particles.

1995

The first commercial Asymmetrical Flow FFF (AF4) was developed by Dr Thorsten Klein at Technical University of Munich, Germany. This system brought a new level of automation and separation performance to the market. Following this innovation and in order to accelerate a focused commercialisation of AF4, he founded Postnova Analytics in Munich.

2001

Postnova Analytics acquired FFFractionation, forming Postnova Analytics USA then. The new company became the sole provider of all variants of Field-Flow Fractionation - Light Scattering systems.