Optical Surfaces has been producing optical components and systems including ultra smooth parabolic and toroidal mirrors for demanding applications.

Leading edge applications that have benefited from the company’s ultra smooth off-axis parabolic mirrors include high power laser electron acceleration/beam focusing experiments and MTF measurement systems.

Ellipsoidal mirrors from Optical Surfaces are helping to push the boundaries of telescopic solar research. The company’s high precision toroidal mirrors are helping improve the achievable performance of mass spectrometers.

For example, a 1.3m diameter spherical spectrograph mirror was a key component in producing the first observable evidence of the existence of black holes.

The company’s ISO 9001-2008 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant and vibration is practically non-existent.

With such stable conditions testing - particularly with long path lengths - becomes quantifiable and reliable. Working with these natural advantages is a highly skilled team of craftsmen with a commitment to excellence in both product quality and customer service.

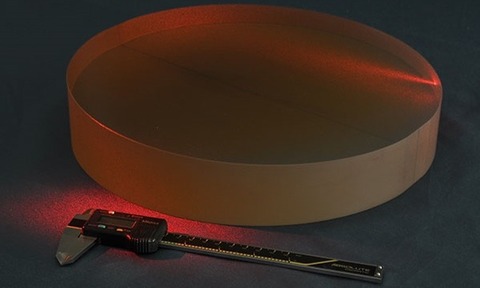

Optical Surfaces’ highly experienced and skilled team of engineers and craftsmen can typically produce off-axis parabolic mirrors up to 600 mm in diameter with surface accuracies to lambda/20p-v depending upon off-axis angles.

With proprietary polishing techniques the company can, depending on the surface accuracy required, achieve the natural limit to the off-axis angle of around 25-30 degrees and surface micro-roughness of ~ 1 nm rms.