The Ismatec Reglo ICC now offers a panel-mount configuration that can be customised with two, three or four fully addressable channels.

Featuring a re-engineered, long-life drive mechanism and available with Windows-based software controls, the panel-mount OEM is ideal for bioreactors, or any instrument containing more than one peristaltic pump.

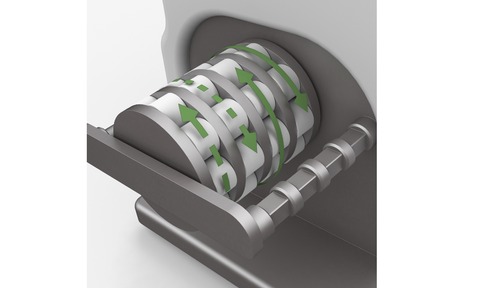

The option of six, eight or 12 rollers allows optimisation of flow rates and pulsation limits while still utilising standard Click ‘n Go cassettes.

Idex engineering director Scott Ellis said: “The ICC in the OEM configuration allows instrument manufacturers to package multiple pump channels into a very small space and utilise simple, modern control protocols.

“The panel-mount ICC can reduce an instrument’s size and part count by eliminating pumps, pinch valves, and solenoid valves; and by reducing the sheet-metal support structure needed for multiple pumps.”

Ellis described the potential benefits an OEM can achieve by replacing four individual pumps with a single ICC.

“When comparing a conventional panel-mount pump array to the ICC, the ICC will typically be 40-50% higher in price per pump. However, one four-channel ICC performs like four pumps in the footprint of one, resulting in a cost reduction of roughly 50%. Plus, the OEM installs only one pump per instrument, not four.”

Part of the fluidic portfolio of Idex Health and Science, the Ismatec Reglo ICC delivers flow rates of 0.001 to 43 mL/min. with post-calibration deviation rates of <5% Accuracy and <1% Precision.

The motor/drive combination enables OEMs to specify pumps with a different number of rollers for each channel.

So a single, four-channel pump might have three channels with 6 rollers for higher flow rates and one channel with 12 rollers for lower flow rates and higher precision.

Idex engineers can also customise the mounting plate and wire harnesses to a customer’s specific application.