FEI has released two application packages for its third-generation Helios NanoLab DualBeam systems, including the plasma-sourced Helios PFIB.

The application solutions address needs in integrated device (IC) manufacturing and failure analysis for fast plan-view delayering and rapid, automated preparation of ultrathin samples for imaging and analysis in a transmission electron microscope (TEM).

Packages are designed to work with various configurations of the Helios platform, including liquid metal (Ga) and plasma (Xe) ion sources.

“Delayering of IC devices is an important tool for semiconductor failure analysis, reverse engineering and circuit edit activities,” said Rob Krueger, vice president and general manager of Electronics for FEI.

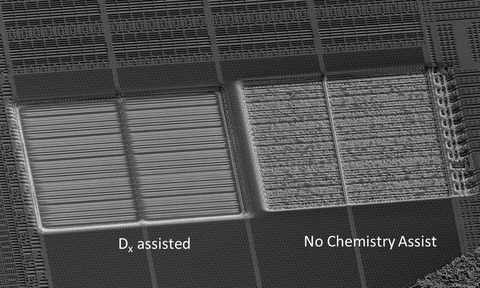

“The new Dx beam chemistry delivers excellent planarity during delayering of mixed field regions, especially for technology nodes of 28nm and below where traditional methods are no longer viable. We have seen high-quality results using both Ga and Xe focused ion beams (FIBs) for front-side and back-side delayering. An additional benefit of switching to Dx for delayering is that the sidewalls of the milled trench are no longer conductive, so we can maintain device functionality if needed.”

Paul Kirby, FEI’s senior product marketing manager for Electronics, added: “TEM analysis is becoming nearly indispensable for process control and failure analysis at advanced nodes where device features are too small to be seen by more conventional SEM-based methods.

“Automated preparation of ultrathin samples that are only a few tens of nanometers thick, which is required for TEM, has contributed to greatly increased productivity and reliability of TEM analysis. The new AutoLXTM package, based on FEI’s iFast Automation software, fully automates the in-situ lift out process, which locates and extracts a site-specific thick section containing the targeted feature and mounts it on a grid ready to be thinned to its final dimensions.”

Kirby added: “For labs already using iFast recipes to create these thick samples, the addition of the AutoLX package opens up the door to increased productivity and more efficient use of valuable human resources.”