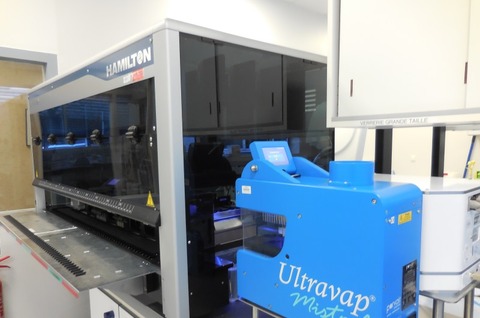

A French pharmaceutical company is using Porvair Science's Ultravap Mistral blowdown evaporation system with a Hamilton Star robotic liquid handling system to enhance new drug candidate processing in its medicinal chemistry department.

Using the Ultravap Mistral the pharmaceutical scientists have been able to remove the traditional ‘bottleneck’ of solvent evaporation from microplates by automating the time consuming step.

Set-up for unattended operation, system performs an

evaporation every 20 minutes. The level of liquid is checked by the robot after each cycle and the needle depth is automatically modified to be about 1cm above the liquid.

The Ultravap Mistral has been designed to allow robots with standard gripper arms to place and remove microplates directly onto its shuttle platform.

Its software enables control all required robotic liquid handling functions, as well as the programming of evaporation at a suitable rate for each solvent type.

Designed to be automation-friendly, the Ultravap Mistral increases sample throughput using advanced evaporator head technology and an innovative manifold design, which directly injects heated nitrogen into each individual well of the microplate simultaneously.

Installation requires only connection to a gas supply and mains electricity. Safety of operation is ensured as this CE-marked compact unit fits into all fume cupboards and boasts full integral fume management within the unit.