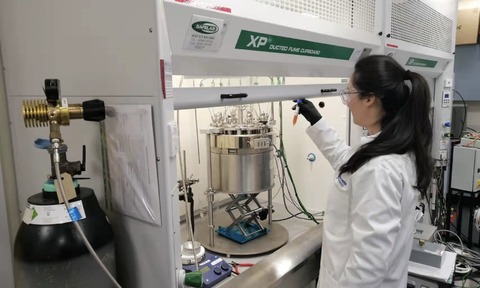

The Process Intensification Group, within the School of Engineering at Newcastle University, UK is using the Asynt’s MultiCell-PLUS High-Pressure Reactor as part of its program of ongoing research to create an environmentally friendly generation of catalysts for production of biorenewable chemicals.

A key objective for the Process Intensification Group has been to develop affordable, less hazardous catalysts to achieve similar function and performance to those currently available, keeping synthesis simple and easy to scale up. Dr Fernando Russo Abegão, a Lecturer from the Group, said “In order to develop our new generation of catalysts we needed to be able to screen a high number of samples, often at high pressure and temperature. In the past we only had isolated autoclaves in the lab. These weren’t ideal for screening as they required large amounts of catalysts for testing, and we could only perform one reaction at a time. To be effective we required an instrumental set-up that could provide a fast turnaround, allowing us to quickly test, rationalise, and identify optimal catalyst formulations.”

Dr Kamelia Boodhoo, a Reader in Sustainable Process Technology, added: “For screening of heterogeneous catalysts, mass transfer can play a big role in the process. We wanted to ensure that we selected a high-pressure reactor system that was well stirred to keep the particles in suspension at all times, reducing mass transfer limitations. This enabled us to screen the catalyst intrinsic activity, rather than having the results masked by mass transfer limitations.

Accurate temperature control is also very important – a few degrees under the desired temperature and the reaction won’t progress fast enough, a few degrees above, and we experience unwanted side reactions. We looked at various commercially available high-pressure reactors and chose the MultiCell-PLUS system from Asynt as it incorporated parallel agitated reactors with automatic temperature and pressure control.

Using this versatile, high-performance system we have already successfully developed a new generation of ‘greener’ catalysts for dehydration of C5 and C6 sugars into furans. Looking to the future, our plan is also to use the MultiCell-PLUS for screening of solvents and process conditions.”

The Multicell-PLUS was developed by Asynt to provide a flexible and customisable device for high throughput screening of chemical reactions under high pressure. The reactor allows users to set up a multitude of experimental conditions in each of its eight reaction cells, suitable for optimisation and screening investigations.

Manufactured from 316 stainless steel, the Multicell-PLUS standard unit operates up to 50 barg and up to 200 ºC. For more demanding and corrosive chemistries, there are options for alternative alloys and for increased operational conditions up to 200 barg and 300 ºC. Motor-driven magnetically coupled overhead stirring is offered as an option for reactions involving particulate suspensions or viscous reaction mixtures. Additional features include a safety-locking mechanism and adjustable support lifting platform.

For further information on the MultiCell-PLUS please visit https://www.asynt.com/product/multicell-plus/ or contact Asynt on +44-1638-781709 / enquiries@asynt.com.