Cole-Parmer's C-FLEX tubing combines smooth inner bore with heat sealable and bondable properties, making it suitable for laboratory and pharmaceutical research.

C-FLEX tubing is a flexible transfer tubing that is an economical alternative to platinum-cured silicon.

This thermoplastic elastomer tubing is designed to meet the standards required for applications in areas including medical, diagnostic, research, pharmaceutical and biotech.

Application uses of C-FLEX tubing include sterile dispensing systems, pharmaceutical production, cell fermentation, cell culture, vaccine production, drug delivery and reagent dispensing.

Manufactured in accordance to GMP standards, this flexible tubing is extruded to precise internal diameter (ID), outer diameter (OD) and wall dimensions.

The C-FLEX tubing is FDA-compliant (21 CFR 177.1810), meets USP 23 Class VI and USDA requirements.

Free certificate of compliance can be requested at the time of ordering.

According to the company, the C-FLEX range combines tensile and tear strength with chemical resistance, biocompatibility and low gas permeability.

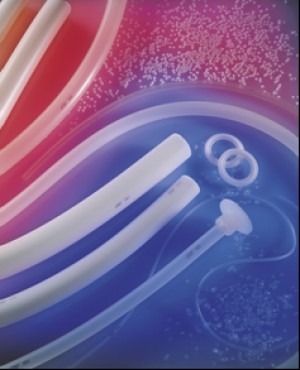

The tubing has a smooth surface and comes as transparent (clear and animal-free formulation) and opaque white.

All three C-FLEX tubing formulations are available in sizes from 1/50in (0.5mm) to 1/2in (12.8mm) ID.

C-FLEX tubing remains flexible over temperature range between -67 and 135C and pressure up to 13 psi at 70C.

Sterilisation can be done by autoclave, ethylene oxide or gamma irradiation.

It is heat sealable and bondable, which makes it suitable for use with single-use bio-processing and bioreactor bags.