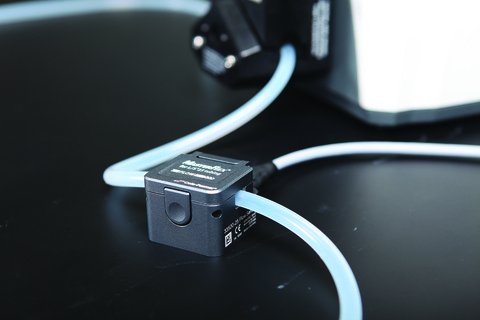

Cole-Parmer launches Masterflex Ultrasonic Flow Sensors, designed to accurately and non-invasively measure the flow rate of liquid in tubing used with peristaltic pumps.

Because the ultrasonic sensor never contacts the working fluid, it is reusable in single-use applications and yields significant recurring savings over disposable sensors. An optional communications package allows users to adapt the flow sensor to their specific application, as well as monitoring and recording data.

Each sensor is optimised for Masterflex tubing sizes and comes calibrated to national measurement standards for Masterflex platinum-cured silicone tubing formulations and water-like fluids. The sensor can be adapted for use with other working fluids or Masterflex tubing materials of the same size with the optional communications package. It is suitable for monitoring flow rates during mixing, filling, fermentation, perfusion and filtration applications.

Using the optional communications package, users can adjust parameters including tubing material, working fluid and temperature according to application. Data can be monitored in realtime graphically, or can be recorded and exported for analysis. the sensor connects directly to a computer or to any meter or controller that accepts RS-485, 4 to 20 mA, 0 to 20 kHz, or PNP-NPN push-pull inputs.