Cranfield University is using MilliGascounter (MGC) meters to measure ultra-low flow rates.

With an accuracy of /- 3 per cent the meters can measure flow rates of all clean gases (including corrosive gases) from 1 ml/hr to 1 litre/hr at input pressures of between 5 and 100 millibar.

These meters are being used by researchers at Cranfield to measure the flow rate and total volume of biogas production in sludge anaerobic digesters of around 0.5 to one litre capacity which are placed in a warming water bath in laboratory conditions.

The meters were selected because they need to be flexible enough to be used in larger volume digesters if necessary.

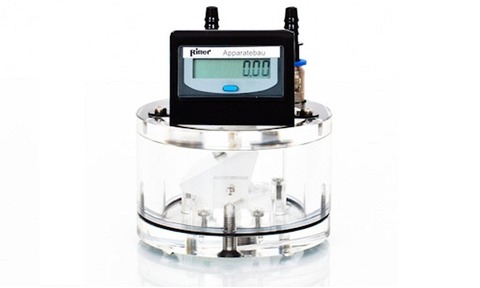

Each MilliGascounter meter can be supplied with an LCD display or with Rigamo data acquisition software and the necessary digital input modules (DIM) and cables to connect the unit to the USB port of a computer.

The gas to be measured flows into the meter via the gas inlet nozzle through the micro capillary tube located at its base and up into the liquid casing, which is filled with a packing liquid.

The gas rises as small gas bubbles through the packing liquid into one of two measurement chambers.

When a measuring chamber is filled the buoyancy of the filled chamber causes the measurement cell to tip over so that the second measuring chamber begins to fill and the first empties.

The measurement of gas volume therefore occurs by counting the tilts of the measurement cell.

The tilting of the measurement cell creates a pulse via magnetic sensors on top of the chambers which is registered by a counter unit. The measured gas escapes through the gas outlet nozzle.