Researchers have been able to scale-up the continuous process for chlorination of primary alcohols using a Syrris Asia 110 system.

The research team, led by experts from the Christian Doppler Laboratory for Microwave Chemistry (CDLMC) and Karl Franzens University (KFU), employed the method of continuous flow processing in a high temperature/ high pressure regime, preparing the yields of n-Alkyl chlorides in the microreactor environment.

The team demonstrated that long-chain primary alcohols can be safely converted into alkyl-chlorides using sealed-vessel microwave processing on laboratory scale within a 10-minute reaction time.

In similar experiments previously, hydrogen chloride gas in a gas/ liquid phase-transfer catalytic system had been used, but the researchers believed their method was safer and more reliable.

The chlorodehydroxylation of primary alcohols used by the CDLMC and the KFU incorporated a scalable generation of n-hexyl chloride as the model substrate.

The team believed this strain of conversion offered significant industrial interest as alkylation agents and synthetic intermediates.

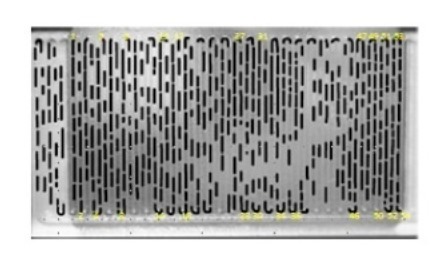

The Syrris Asia 110 seeked to create reproducible optimum conditions for the preparation of n-butyl and n-hexyl chloride using a microchip reactor and a reaction temperature of 160-180°C.