Experts from Uniqsis have shown how its proprietary glass static mixer-reactor chip technology can be used to perform exothermic reactions.

The innovative technique incorporates performing the reactions at higher temperatures under continuous flow-through conditions.

In an effort to achieve high levels of reproducibility and facilitate scale-up, the researchers maintained control of both mixing and temperature, particularly for rapid mixing-dependent reactions.

Low-temperature metalation-quench reaction can be performed at a raised temperature

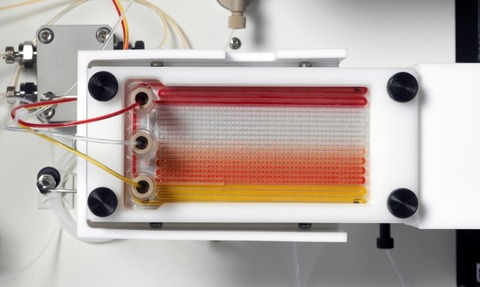

In some cases, the diffusional mixing provided by simple T-piece mixers is too slow to afford the necessary control and the team had introduced a range of glass static mixer blocks that integrated channels with active mixing geometries.

These are capable of providing efficient turbulent mixing throughout the reaction vessel, whilst also functioning as a heat exchanger.

The metalations performed are typically conducted at temperatures around -78°C with slow addition of the organometallic base, a process which helped control the exothermic nature of the reaction.

Application note 25 demonstrates how a low-temperature metalation-quench reaction can be performed at a raised temperature using a mixer-reactor chip in combination with a FlowSyn cold coil.

The Uniqsis system offers conventional 2 input 1 output static glass mixer/ reactor chips and a 3 input 1 output chip which is designed for ‘quench’ input reactions.

To read application note 25, please click on the link above.