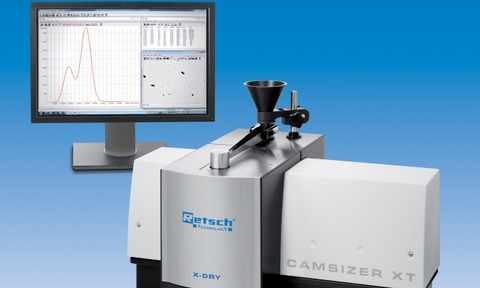

The Camsizer XT from Retsch Technology is designed to offer a wide measurement range and variable dispersion methods during particle analysis.

The quality control of fine powders in a size range from 1µm to 3mm can be improved with Retsch Technology’s Camsizer XT, the company claims.

The design of the Camsizer XT is based on the optical particle measurement system Camsizer but has been optimised for finer samples.

Fine particles tend to agglomerate which makes it difficult to record the properties of a single particle. Therefore, it is important to have various possibilities of feeding the sample to the analysis area, in order to be able to find the optimum between the desired dispersion of the agglomerates and the undesired destruction of the individual particle for each material.

The XT offers three alternative dispersion methods: Pourable, not agglomerated particles are fed to the analysis area by the vibrating feeder of the ’X-Fall’ module.

Secondly, with the ’X-Jet’ module agglomerated particles can be accelerated and dispersed through a nozzle with adjustable overpressure.

Thirdly, particles can be dispersed in liquids in the wet module ’X-Flow’, optionally with ultra sound. It is therefore possible to choose the optimum method for each sample type.

Features overview:

- Digital image processing with two-camera-system.

- Wide dynamic measuring range from 1?m to 3mm.

- Reliable detection of smallest amounts of “undersize” and “oversize”.

- Modular System ’X-Change’ for dry and wet dispersion.

- Measurement results are 100% compatible to sieve analysis if required.