Culture change

11 Aug 2014

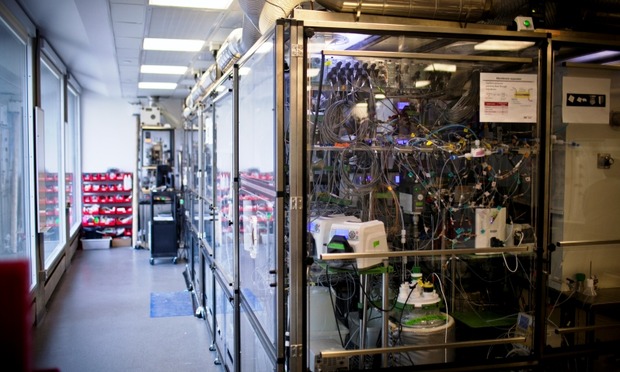

Is more laboratory analysis and experimentation the key to making bioprocessing breakthroughs pay their way, asks Louisa Hearn.

The age-old practice of fermentation demonstrates the life-changing potential of harnessing the biological reactions we now refer to as ’bioprocessing’.

Recent scientific developments have opened the door to industrial-scale developments far and wide, from the formation of therapeutic pharmaceuticals to organic solvents destined to replace toxic chemicals.

By definition, a bioprocess uses living cells or components of cells to manufacture new products and many of these processes are the result of a complex series of reactions to environmental conditions.

“The early research stage in biologics is all about identifying the best process

TAP Biosystems’ strategic MD Tim Ward

But accurately measuring and controlling the laws of chemistry and physics throughout the early stages of product development can be the vital ingredient to making products commercially viable, say industry experts.

TAP Biosystems, which is now part of the Sartorius Stedim Biotech Group, supplies a range of cell culture and fermentation systems to the biopharmaceutical market, and develops tools for the process development of protein-based therapeutics.

“Our focus today is in the early stages of development and optimisation of processes around producing biologics with cells,” says Tim Ward, TAP Biosystems’ strategic marketing director.

TAP’s key customer base is the biopharmaceutical industry, where reproducible results in the laboratory must be developed before scaling up to the commercial production of therapeutic cells.

“We have developed a lot of tools around the particular problems they have,” he says.

It has two very closely linked products that have been developed by the company. The first is the ambr15, which is focused on automating early processes of cell line selection and development, as well as the early stages of process and media development.

More recently it has launched the ambr250, which allows users to take the cell lines they have optimised and conduct process development and optimisation.

“The early research stage in biologics is all about identifying the best process to manufacture the molecule you will be using, and this can significantly affect the economics of what you are going to produce,” says Ward.

“Getting the right level of productivity from a cell line is important and that is all about choosing the correct cell lines that will continue to perform well as they go through the scale up process,” he says.

“If you choose a poor cell line in the beginning you may eventually discover you need to double the size of your manufacturing facility.”

For example, if you test the performance of the process over a range of temperatures and confirm that the resulting product retains its critical quality attributes, you know that if you stay within this range during manufacturing - and can accurately monitor the key parameters of your process - your batch is okay to use, says Ward.

“This means you have to do a lot of experiments testing the effect of different parameters, and you need to test the boundaries - or design space - of each process.”

This is where the ambr250 product comes in.

“It allows you to run a lot of parallel experiments - and gives you control of a lot of process parameters - so you can design experiments to test those, and then look at the output of each test,” he says.

The other aspect is the integration of analytical software to monitor what is going on as laboratory staff control the process and run experiments.

“Conventional bioreactors take up a lot of space, and you need a lot of people and infrastructure to operate them and keep them clean,” says Ward.

“Tools such as ambr250 allow you to run all your bioreactors in one go. There are tools to do measurements of cell cultures as you go along and the single-use fully disposable reactors mean you don’t need all that additional infrastructure to manage and clean the equipment.”

Without this type of technology, he says there is a far greater risk of the resulting product failing to meet the desired specifications.

“In this scenario it can take much longer to do trial and error experiments because you are not as aware of the underlying impact of different parameters on the output of the processes, in order to comply with the regulations created to ensure the quality of drugs and that they are safe and effective.”

Companies can also incur very large costs if they lose an entire batch, he adds.

Mettler Toledo, which supplies a range of instruments to bioprocessing laboratories, has also developed process analytical technologies (PAT) to track critical process parameters and quality attributes for the biopharmaceutical sector.

“By understanding how particles change in real time, researchers can track batch-to-batch consistency, viability, cell growth or aggregation, detect endpoints, and optimise downstream recovery and purification process,” says Yvonne Appoldt, marketing manager in the laboratory division of Mettler Toledo.

Another shift in the pharmaceutical and fine chemicals industries is the call to replace batch processes with continuous production processes in manufacturing.

“Continuous processing offers several advantages over start-and-stop batch production. A continuous-flow reactor requires less space and less investment. It can provide better control over reaction conditions and productivity, and continuous methods can often be used to rapidly scale up reactions, including ones that involve hazardous reagents,” quotes Appoldt from a recent Chemical & Engineering News article.

Although many companies are considering continuous reactions mostly for new products or to lower the cost of making generic drugs, many are reluctant to change processes for approved products, she says.

“Due to this reluctance to change, new technologies, products and services are not adopted to the extent they could be.”

Berhardt Trout, director of the Novartis-MIT Center for Continuous Manufacturing, says his key objective is to move pharmaceutical manufacturing processes from the 19th century into to 21st century.

“Due to this reluctance to change, new technologies are not adopted to the extent they could be

Mettler Toldeo marketing manager Yvonne Appoldt

“We’re still really using old techniques and approaches. The focus should be on efficiency and quality in the sense of better process understanding leading to better product understanding.

“We should be moving from the approach where one does experiments in the lab, and then does pilot and then scales up to commercial, to an integration of the lab work with the pilot and scale work,” he says.

Massachusetts Institute of Technology (MIT) and pharmaceutical company Novartis have launched a joint research effort to transform those procedures, building a drug-manufacturing prototype that can transform raw materials into tablets in a nonstop process.

“We need to have a much better process understanding and we need to gain that understanding in the lab. So we’re pushing industry to do more front-end loading research and lab work so they have better understanding of the behaviour of key aspects of the process,” says Trout.

“Part of this is to boost efficiency but really it is just a better way of doing business.”