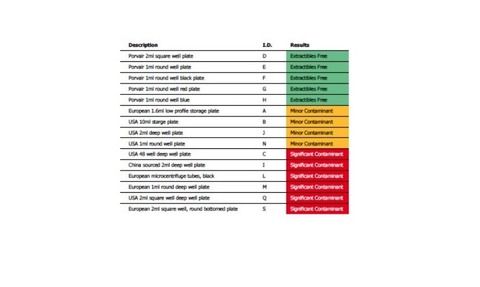

Porvair Sciences has announced that a recent study by the Department of Chemistry at the University of Kent, UK revealed significant levels of contamination found in more than 50% of the commercially available deep well microplates tested.

The study, following on from an earlier study in 2005, gives data on a large range of microplates from numerous manufacturers based in Europe, USA and China.

According to reports, mass spectral data shows that persistent contamination from a range of compounds found in the raw polymer master batch continues to be evident in many of the microplates tested.

The effect of extractables leached out of the deep well plates identified in this report depends on the exact application for which the plate was designed but is highly likely to significantly affect their performance and contaminate samples stored in them, Porvair claims.

The authors of the report conclude it is likely that a low-grade polypropylene was used in the production of many of the microplates that leached extractables when tested.

Such low-grade polypropylene often contains flow modifier additives or “mould release agents” which will have been used to ease the manufacturing process and help free the moulded microplate from the mould respectively, Porvair says.

The solvent used for “extraction” of potential leachates in this study was methanol.

As mass spectral testing was undertaken after only 24 hours, it is clear that samples do not have to be in these plates for very long before they can become contaminated.

For a copy of the full study, please visit: www.microplates.com