Porvair Sciences has expanded its range of high integrity heat sealing films for microplates and tubes to includes clear, strong (Dura), heavy duty and gas permeable products.

Choosing the correct combination of seal and closure device for different types of microplate is important to achieving good laboratory practice and avoid unnecessary work further downstream. Microplates are convenient for storing, transporting and handling compounds and samples, but common problems include evaporation from the wells of the plate, contamination from dust, spores or other atmospheric detritus and spillage whenever they are used for transport. Additional risks of cross-contamination in denser formats such as 96- and 384-well plates demonstrate why it is important to find the most effective seal and closure device are an important consideration.

Porvair’s high integrity heat sealing film range includes variations to add flexibility and compatibility to suit all requirements for sample storage and collection. When heat is applied to these products, a tight seal is formed on polypropylene, polyethylene, polystyrene, polycarbonate and cyclin olefin copolymer (COC) microplates and tubes.

Optically clear films from Porvair are available in a variety of formats including peelable and pierceable and strong non-peelable. The seals are suitable for a wide range of applications including imaging, fluorescence, colorimetric assays and PCR/qPCR. All clear seals are also compatible with devices that use a heat pressurised lid.

The Dura range of durable foil-based heat-sealing films are suited for high temperature applications and room temperature storage. They come in peelable, solvent resistant (including DMSO) and pierceable formats. All the Dura heat sealing films are autoclavable.

For long-term storage and transportation, Porvair has introduced the HD Heat seal. This range of heat-sealing films offers the strongest protection of any of the Porvair range. Key properties of HD Heat seals include high resistance to a broad range of solvents, wide seal integrity range (80°C to 110°C) for polypropylene plates and durability (not penetrable by pipette tips and liquid handling systems).

The company has also introduced the Bio Pierce and Peel seal, which is specially designed for use in cell culture applications. Based upon a non-woven gas permeable material which limits evaporation – the porous properties of the Bio Pierce and Peel seal allow gas exchange to occur whilst providing an inert surface and no adhesive to interfere with the microplate well contents.

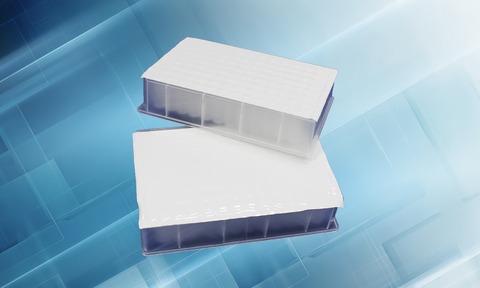

The extensive range of high integrity heat sealing films is complimented by Porvair’s microplate and tube closure devices – from small manual to fully automated heat-sealing systems such as the UltraSeal Pro (https://www.microplates.com/ultraseal-pro/).