Porvair Sciences provides a complete design and manufacture service to help customers develop new and innovative custom microplates for specialist applications.

The company is widely recognised in the field of moulding ultra-pure plastic materials such as polystyrene, polypropylene and polycarbonate. It has decades of experience and expertise in ultrasonic welding, surface treatment techniques, co-sintering of polymers/silicas, specialist assembly and a strong understanding of analytical applications – making it a suitable OEM partner for development and production of optimised custom microplates solutions.

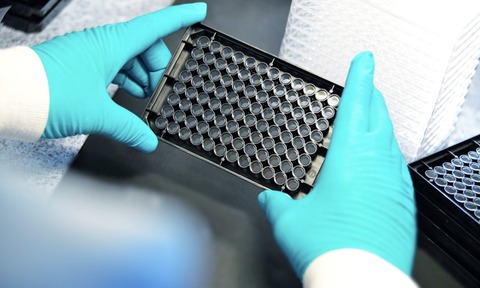

Porvair’s team of engineers and creative thinkers can help in the development of high quality products for filtration, storage and separation – from single well up to as many as 1536-well microplates. When combined with it manufacturing expertise in co-sintering plastic polymers, the company can push the boundaries of microplate design for life science and analytical markets.

Krzysztof Kielmann, Microplates Product Manager at Porvair Sciences said: "Our flexible cleanroom class 100,000 production facility is perfectly suited to produce custom microplate products of the highest quality, free from any contaminants, to suit initial trials right up to fully automated production runs.

"Customer feedback indicates it is our innovative designs, rapid prototyping, application knowledge and automation-friendly high precision moulding capabilities that were key criteria in Porvair's selection as an OEM partner for specialist application optimised microplates.”

For further information on Porvair Sciences custom microplate design and manufacture service please visit https://www.microplates.com/custom-manufacturing/ or contact the company at int.sales@porvairsciences.com or call +44 1978 666222 / +1 800 552 3696.