Tecan and TAP Biosystems are to automate RAFT 3D cell culturing on the Freedom EVO.

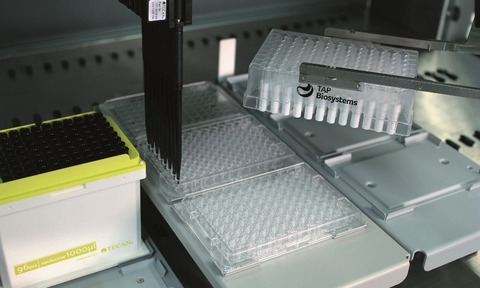

Tecan and TAP Biosystems have announced a co-marketing agreement to further expand the automated 3D cell culture capabilities of the Freedom EVO liquid handling platform.

Automation of TAP’s collagen-based RAFT cell culture system will allow scientists to quickly and conveniently create 3D cell cultures in a 96-well, SBS-format.

The RAFT 3D cell culture system uses biologically relevant concentrations of collagen matrix to ensure cells grow and proliferate in an environment closely resembling the native tissue.

The Freedom EVO workstation is configured with a number of modules, including reagent and microplate cooling units and a heated shaking device, to provide fully automated preparation and maintenance of RAFT cell cultures.

This, according to the company, ensures rapid, reliable creation of consistent and reproducible 3D cell cultures, offering walkaway processing for a wide range of cell biology applications.