The FlowCAM-ES automatically detects, images, counts and measures metal particles in rinse water.

Operating on-line within the production or processing line, the newest FlowCAM automatically extracts, dilutes and runs samples of the wash water, taking a hi-resolution, digital image of each particle detected.

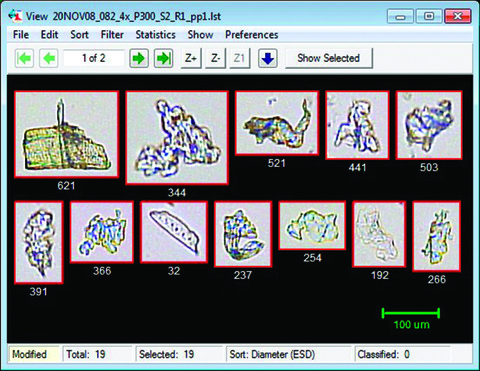

The system reveals a particle’s actual size and shape using more than 30 different measurement parameters in real-time.

According to the company, this verifies the effectiveness of the rinse step in removing contaminants and is designed to eliminate the risk of further contamination or error due to human involvement.

Aimed at lab managers, process engineers, cleanroom managers and others responsible for product purity and quality assurance, the in-line FlowCAM is able to image thousands of metallic particles in seconds.

The patented FlowCAM technology tests wash water from medical and surgical devices, pumps, silicon wafers, laboratory glassware and other high purity products where particulates typically measure from 2 um to 800 um in size.