Pumping out particles

16 Jul 2014

UK-based nanoparticle manufacturer is scaling-up its production capabilities.

Promethean Particles is stepping up its nanoparticle manufacturing capabilities from pilot-scale production offering only kilogram quantities of materials up to a 100 tonne-per-year plant.

In order to achieve this, the company is developing a reactor plant using high-pressure triplex plunger pumps from Cat Pumps.

Promethean Particles has already demonstrated the scale-up potential of the technology with its pilot scale reactor system which has successfully manufactured nanomaterials continuously for 60 hours, the company says.

“We knew that positive displacement pumps were the only viable solution for scaling up the process

SHYMAN project engineer Lewis Neve

A spin-off from the University of Nottingham, Promethean Particles produces nanoparticles using continuous hydrothermal technology.

In hydrothermal synthesis, the hot, pressurised water is mixed with a metal salt solution, such as iron nitrate, and a reaction occurs - the salt is dehydrated - and nanoparticles are formed. It is the high pressure positive displacement triplex plunger pumps that are used to help create the continuous pressure and fluid flow that is a key element in the process.

The University of Nottingham commenced its research into optimising supercritical water hydrothermal synthesis for nanoparticles around 14 years ago.

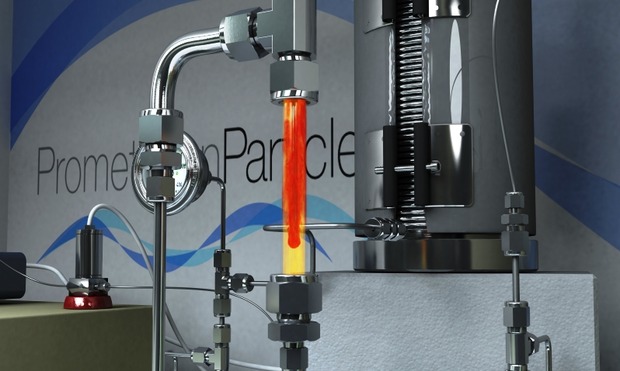

The result of the university’s work was the development of Promethean Particles’ Nozzle Reactor, a customised design that uses the buoyancy induced eddies to produce an ’ideal’ mixing scenario in a pipe-in-pipe concentric configuration in which the internal pipe has an open-ended nozzle.

The supercritical water is fed downwards through the internal pipe and out the end of the nozzle reactor, while the aqueous metal salt stream is fed counter-currently upwards through the outer pipe.

The reactor has shown a dramatic improvement in process reproducibility and reliability as well as providing the ability to control particle properties, such as size, composition and shape, through the manipulation of process variables, Promethean Particles says.

The four Cat Pumps Model 3801 high pressure triplex plunger pumps will be used with the new reactor system for pumping deionised water through a heater that raises the temperature to the super-critical condition of 374ºC at 218 atmospheres.

Triplex PD plunger pumps are typically the chemical engineer’s first consideration when high pressure and high operating efficiency is required.

Triplex PD pumps actually increase in efficiency even further at higher pressures and are most widely used in applications where the pumped liquid is of low to medium viscosity and has little inherent lubricity.

Cat Pumps general manager Brian Hubbard says: “We worked with Promethean from the early stages of the scale-up project, helping the scientists to develop a pump specification and then offering the most elegant solution both technically and commercially.”

Hubbard says his company recommended its Model 3801 as it offers the required combination of flow, pressure, materials compatibility and features, including the facility to flush the pump seals which future-proofs the installation needed by Promethean Particles.

“By pairing up two pumps for the highest capacity duty, and two more solo pumps for the mid-flows, we’ve also given Promethean a high level of commonality and standardisation,” Hubbard says.

Results obtained from the pilot model proved that scaling to a much larger commercial reactor was viable.

Therefore, both companies had some major decisions to make in terms of the pumping capability for the de-ionised water feed.

“From our experience with the bench and pilot reactors, we knew that positive displacement pumps were the only viable solution for scaling up the process to commercial viability,” says Lewis Neve, lead chemical engineer on the SHYMAN project.

Promethean Particles is participating in the EU FP7 funded Sustainable Hydrothermal Manufacturing of Nanomaterials (SHYMAN) project. This project is based on Promethean’s proprietary technology and its aim is to scale up nanomaterial production while maintaining a sustainable, low-cost process for producing high quality materials.

“Originally the pilot plant used two single head piston-activated diaphragm pumps and these displayed marked signs of pulsation. A further issue was that they were at the edge of their capability range in terms of pressure and flow, so they would not be suitable for the much larger reactor,” Neve says.

“We chose Cat Pumps because they are a well-established international manufacturer and could provide details of similar projects where their pumps had run for many years and this gave us confidence.”

Promethean Particles suggests that its work with Cat Pumps will be fundamental to the up-scaling nanoparticle production from a batch to a continuous process.