Autoscribe’s Matrix Gemini Laboratory Information Management System (LIMS) has been selected for use in WMG’s Energy Innovation Centre.

As well as being a leading research and education centre, WMG is one of seven world class centres of industrial innovation that make up the High Value Manufacturing Catapult project.

This was set up to accelerate new concepts through to commercial reality and in doing so provide a catalyst for the future growth and success of manufacturing in the UK.

The centre provides facilities to undertake a wide programme of tests on battery technologies, from cell to pack level, for both private and commercial projects.

The majority of work involves testing Lithium-ion batteries for hybrid vehicles and all-electric vehicles, although other battery technologies are tested.

Matrix Gemini was chosen because of the flexibility of configuration, and all system changes and developments are being handled internally by WMG’s Energy Storage and Management Research team using the One Time Configuration Tools.

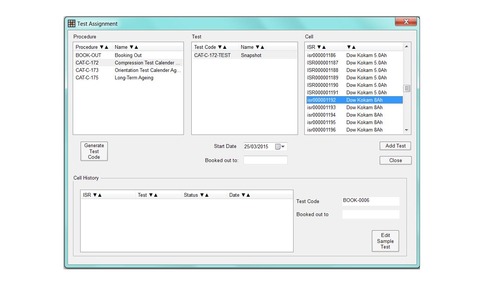

Typical tests include: ageing tests, thermal testing and abuse and vibration testing, with results collated and returned to clients.

With around 2000 sample items in store and a few hundred in active testing, approximately 1TB of data is created each year and can be in many forms, such as proprietary databases, images and video.

The test results are stored externally and Matrix Gemini is able to track metadata that points to the raw data so that test results can be tracked.

Autoscribe’s managing director John Boother said: “This is the latest example where Matrix Gemini has been chosen due to its ability to be readily configured to the laboratory’s specific current requirements while retaining the flexibility to be modified by the users themselves as needs change.

“We also understand that all of the other systems evaluated by WMG were designed for more traditional laboratory environments and couldn’t easily be adapted to WMG’s needs.”