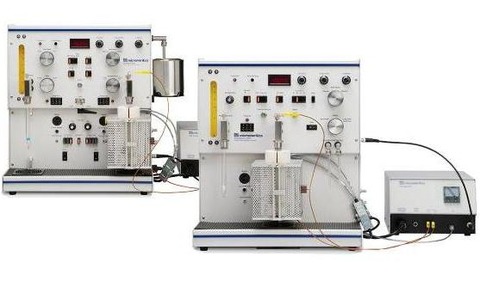

Micromeritics ChemiSorb HTP offers high-resolution and high-throughput chemisorption analysis for catalyst manufacturers and researchers, especially those needing accurate analysis of large numbers of samples in a relatively short space of time.

Optimising the design and utilisation of a catalyst requires detailed understanding of the catalyst’s surface structure and chemistry.

Using the ChemiSorb HTP it is possible to determine active metal surface area, percentage metal dispersion, surface acidity and the size of active particles.

Chemical adsorption, as implemented by the ChemiSorb HTP, involves the sharing of electrons between a gas and the solid catalysis surface, making it a much stronger bond than physical adsorption. It is also a single layer phenomenon because adsorption will cease when the adsorbate can no longer contact the surface.

Not only is the ChemiSorb HTP system fully automated, but with six analysis stations it also enables multiple analyses to be run at the same time.

The manifold vacuum system constantly monitors pressure transducers at each of the analysis stations. Each analysis port is independently accessed and equipped with its own furnace, featuring a user defined temperature range from 10ºC above ambient up to 700ºC.

A mass flow controller is also installed at each port, ensuring accurate and reproducible gas flow through the sample with up to twelve different gases attached and available at any one time.

Operators can specify different equilibrium times thanks to the equilibrium option. Moreover, because temperature is recorded with each equilibrium pressure the highest quality isotherms are obtained. The analysis program operates in a Windows environment, making it easy to manipulate and customise reports.

Chemical adsorption analysis can also provide important information required for catalyst evaluation after a period of use as well as during the design and production phases.