The Rutherford Appleton Laboratory is using an ultra high precision off-axis parabolic mirror in its Vulcan laser experiments.

The ultra smooth mirror will form a crucial focusing element in the Rutherford Appleton Laboratory’s (RAL’s) ongoing experimentation using the Vulcan Nd:Glass High Energy Laser.

Trevor Winstone, Operations Manager for the Vulcan Laser at RAL commented “The F/15 off-axis parabola will be used for experiments that require long Rayleigh focal length such as electron acceleration experiments”.

The advance in laser technology to ultra-high intense (>1018Wcm-2) short-pulse (<1ps) lasers has made it possible to study laser-plasma interactions at ultra-high intensities.

“Applications include particle accelerators, inertial confinement fusion schemes and also biological and medical technologies. He added “We selected Optical Surfaces Ltd to supply this precison focusing optic because of their long proven track record in manufacturing and supplying high quality, demanding optics to ultra high power laser facilities around the world”.

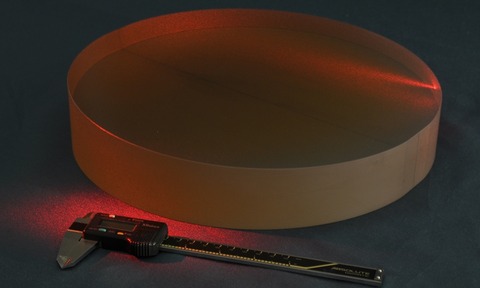

Using proprietary production techniques, Optical Surfaces produced the 320mm diameter off-axis parabolic mirror with a surface accuracy of better than lambda/8 P-V, surface gradient of better than lambda/20 P-V and smoothness of 20/10 scratch/dig.

The off-axis mirror was manufactured in ClearCeram HS and coated using a special high performance coating to produce high reflectivity (R>99%) at 1053 and 527nm.

Dr Aris Kouris of Optical Surfaces Ltd. commented “ The most demanding part of the producing this demanding optic was to achieve the surface gradients which required an iterative process in order to achieve the required smoothness.

“To achieve lambda/20 P-V surface gradients specification using an iterative process added a significant amount of handling during the manufacturing that increased the risks for markings. Fortunately our skilled craftsmen are highly experienced in handling optics and maintaining a very high surface quality.”