The latest range of 1200ºc muffle furnaces provide rapid and uniform heating from a bench top unit.

The furnaces are available in chamber sizes ranging from 5.2 up to 20 litres to cater for a wide range of workloads and laboratory heating applications including quality control testing, ashing, heat treatment, preheating, melting, metallurgical research and sample production.

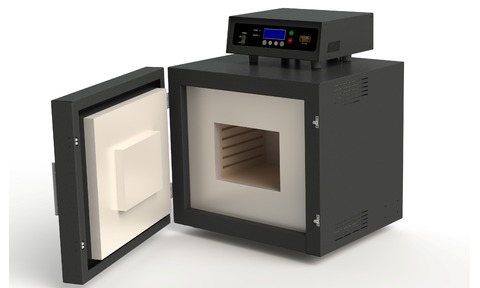

The inner chamber walls are constructed using insulated fire bricks which provide optimum insulation as well as protection against mechanical abrasion, thermal ageing and deformation.

A uniform temperature spread is achieved as the heating elements are located on both the sides and the top of the chamber and they are partially recessed and embedded in quartz sleeves.

This, combined with a standard thickness of the inner chamber material, ensures additional protection and enhances uniform heating of the chamber.

The modular design of the inner chamber enables easy removal and replacement within 30 minutes, while its double skinned construction ensures that the outer casing remains cool to touch, even after prolonged operation.

Further features include a PID controller located on the top of the chamber to facilitate easy viewing and programming during operation and adjustable feet to enable levelling of the unit should bench top surfaces be uneven.