HEL has introduced the Lasertrack online particle-sizing probe, which provides advances in crystallisation and formulation studies.

When combined with a reactor and integrated software, the PAT concept can be readily realised in accordance with the FDA guidance for QbD (Quality by Design).

A PAT strategy for crystallisation-type applications requires a reactor, control software and a particle-sizing probe.

In terms of reactor system, multiple studies often need to be conducted to optimise the process; the use of smaller vessels in parallel is ideal.

Polyblock is an example of a suitable platform where four vessels can be used at totally separate conditions, using samples as small as 10ml and up to more than 350ml, controlled from a single computer.

The heart of the PAT is the data quality from the particle-sizing probe.

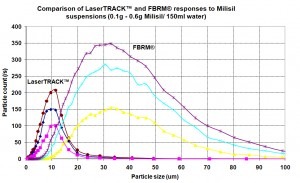

In this example, the data from two probes, the Lasertrack and FBRM, is compared.

The sample is a quartz-based material with a specified mean size of 10um and 95 per cent of particles are below 34um; this was confirmed by electron microscope.

The Lasertrack agrees closely with the specification while the FBRM reports a significantly higher mean size and a very different (much wider) distribution.

Such discrepancies have been found in many side-by-side trials with different materials.