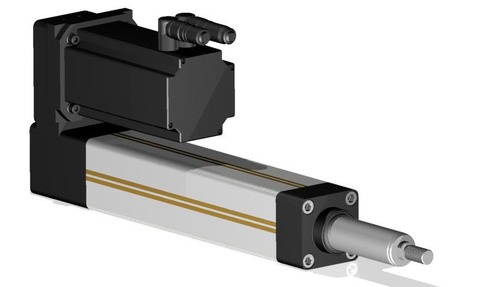

The series of ETH electro-thrust cylinders delivers up to 5 times the force and 10 times the life of the previous ET.

New features include; power density - very high forces in small frame sizes, an integrated anti-rotation device, reduced noise emission, the home/limit switches and cables can be concealed in the profile and a very high service life greatly increasing lifetime up to factor 5.

In some force measurement applications, a force sensor on the cylinder rod is not possible or will affect the application’s scope. For this case Parker have developed a special variant of the ETH cylinder, where the force sensor is integrated into the rear end of the cylinder.

The advantage is that the sensor cable does not move with the rod. All force sensors are configured as traction/thrust sensors and they can be used to measure contact forces or overloads.

Due to the thin film technology, the swivel head force transducers are very robust and have long-time stability.

For precise motion, positioning, setting and actuating, the electro cylinder offers:

· High mechanical efficiency up to 90 %

· Strokes up to 1600 mm

· High traction/thrust force up to 25,100N

· Repeatability up to ±0.03mm

· Speeds up to 1.7m/s

· Toothed belt drive (for parallel motor mounting)

· A range of screw pitches for thrusts from 5 to 32mm/rev.

· 3 (ETH032, ETH050,ETH080)

· Predefined standardised motor and gearbox flanges for simplified selection

· 3 different protection classes available:

IP54 with galvanised screws (standard)

IP54 with VA stainless screws

IP65