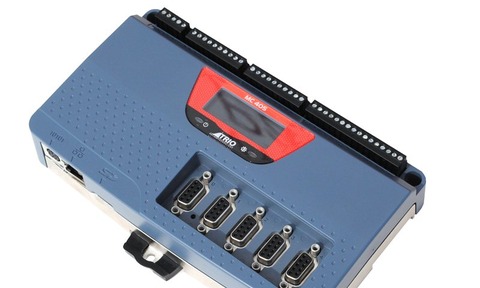

Using the ARM11 processor, the MC405 provides up to 4 axes of servomotor plus a master encoder.

The MC405 features a total of 16 axes in software where any axes not assigned to built-in hardware can be used as a virtual axis.

Features include:

· ARM11 processor with double precision floating point

· Digital / Analogue I/O

· Selectable servo update 125 - 2000 microseconds

· Ethernet programming interface

· CANbus expansion port

· Multi-tasking TrioBasic programming

· IEC 61131-3 programming support

· Micro SD Card memory slot

· Real time clock

· LCD display

The built-in Ethernet port allows programming and connection of common HMI and PLC protocols directly to the MC405.

User programs can be written in Trio’s established multi-tasking TrioBASIC language using the powerful Motion Perfect application development software making complex motion easy.

Also available as an option on the MC405 is the industry standard IEC 61131-3 runtime that is an easy to use fully functional PLC programming system.

A back-lit display enables the controller status to be easily determined, whilst the single piece metal cast back-plate provides an integrated earth chassis to improve noise rejection in the industrial environment.